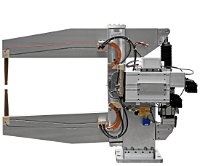

The SPATZ+ complete system is designed down to the last detail to meet the special requirements of aluminium welding. The 1 000 Hz SPATZ+M900 weld timer in master-slave configuration supplies the high welding current of up to 80 kA required for Aluminium welding.

With the welding cabinet and the integrated drive technology for a servo-electric welding gun with servo-electric compensation, the SPATZ+M900 weld timer forms the heart of every MATUSCHEK Aluminium welding system.

The CapClean electrode management system is the second component for Aluminium spot welding suitable for production. By regularly forming the electrodes by means of specific form grinding, it avoids any contamination layer. This ensures reliable welds and up to 20 000 weld spots with the correct electrode contact geometry over the entire service life of the electrode.

The system is completed by a SPATZ+ servo welding gun in C or X design with servo-electric compensation for optimum compensation of the gun weight.

The system also offers a great advantage in terms of material and planning flexibility. Because not only

aluminum but also steel sheets can be joined with high quality using the same equipment. (

Video: spot welding of

steel and aluminum

) Particularly the production lines within automotive sector, can be planned in a cost-saving

manner. Both materials can be manufactured with the same robot cell. The savings potential is enormous. Possible

retooling / reuse is also increased by this flexibility.

The system includes the following components:

|

SERVO WELDING GUNS The SPATZ+ weld timers rare combined with SPATZ+ servo welding guns. |

|

|

FIELDBUS CARDS To expand connectivity and variable system integration, the SPATZ+ weld timers are upgraded with SPATZ+ fieldbus cards. |

|

|

SOFTWARE The entire setting, parameterization and visualization of the welding parameters is carried out by the SPATZ software family. |

|

|

SUPPORT, SALES AND TRAINING We would be happy to advise you on the selection of suitable solutions for your individual welding tasks and inform you about our training portfolio. |