Our power analyzer is designed for interactive testing on multi-channel drive test benches. It streamlines the daily work of developers, analysts, and test teams — intuitive, precise, and future-proof.

Our power analyzer delivers high measurement accuracy and precision, making it ideal for development and data acquisition across industries such as e-mobility, aerospace, and laboratory test benches.

It is perfectly suited for power measurement of drivetrain components such as motors and inverters in the e-mobility sector; for renewable energy applications like photovoltaics and wind power; for household appliances such as washing machines; and for industrial applications including cranes, pumps, and elevators.

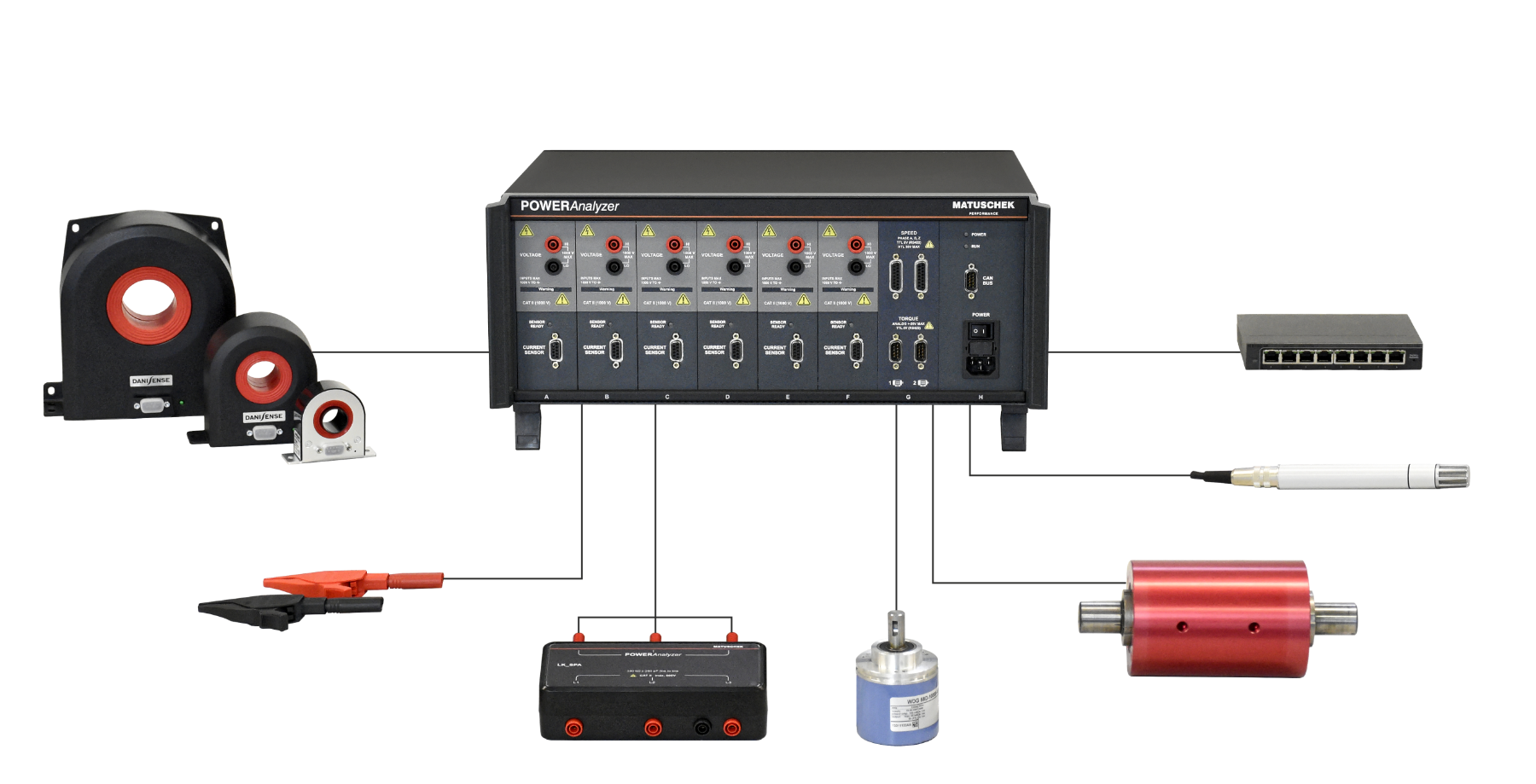

The POWERAnalyzer LK601 can record and analyze up to six electrical phases on the test bench simultaneously with high precision. With the optional dual motor card, two torque sensors and two position signals can also be captured.

Via the standard CAN interface, additional process variables such as temperature and vibration can be recorded. Using the intuitive and customizable POWERStudio software, all settings can be made on the computer, and custom measurement quantities and visualizations can be defined. Data analysis can be performed both internally and externally.

The PC connection is located in a separate base module on the rear of the device.

Technical data of the power analyzer

| Sampling rate | Continuous 10 MS/s per channel |

| Sampling resolution | 16-bit A/D converters, noise-free and distortion-free |

| Voltage ranges | 12 ranges 1.5 – 1,000 V (RMS) |

| Current ranges (external) |

9 ranges 0.5 A – 250 A (RMS) or 1.5 A – 750 A (RMS) or 1.5 A – 1,200 A (RMS) |

| Bandwidth | 1 MHz |

| Accuracy | High, at < 0.05% (of power value) |

| Signal latency | Low, at < 5 ns |

| Number of measurement channels | 7 per device (6 + 1 dual motor card, up to 30 when cascaded) |

| Interfaces | Ethernet, CAN |

| Other | Integrated power supply for external sensors |

| Cascading | Possible for multiple devices |

| RAW data recording | Possible in real time and in parallel for all channels |

The POWERAnalyzer LK601 combines highly accurate and versatile acquisition capabilities with flexible system expandability and intuitive software operation.

The POWERAnalyzer LK601 excels at precisely capturing a broad set of additional signals alongside electrical power parameters. This enables simultaneous acquisition and analysis of numerous physical and mechanical quantities such as temperature, vibration, pressure, sound, speed, torque, friction, strain, acoustics, humidity, force, and many more.

Another key advantage is the intuitive operation via modern PC software — this user-friendliness significantly simplifies handling.

In addition, the system offers easy expandability and customization. Users can flexibly adapt the system to their specific requirements to achieve optimal measurement results.

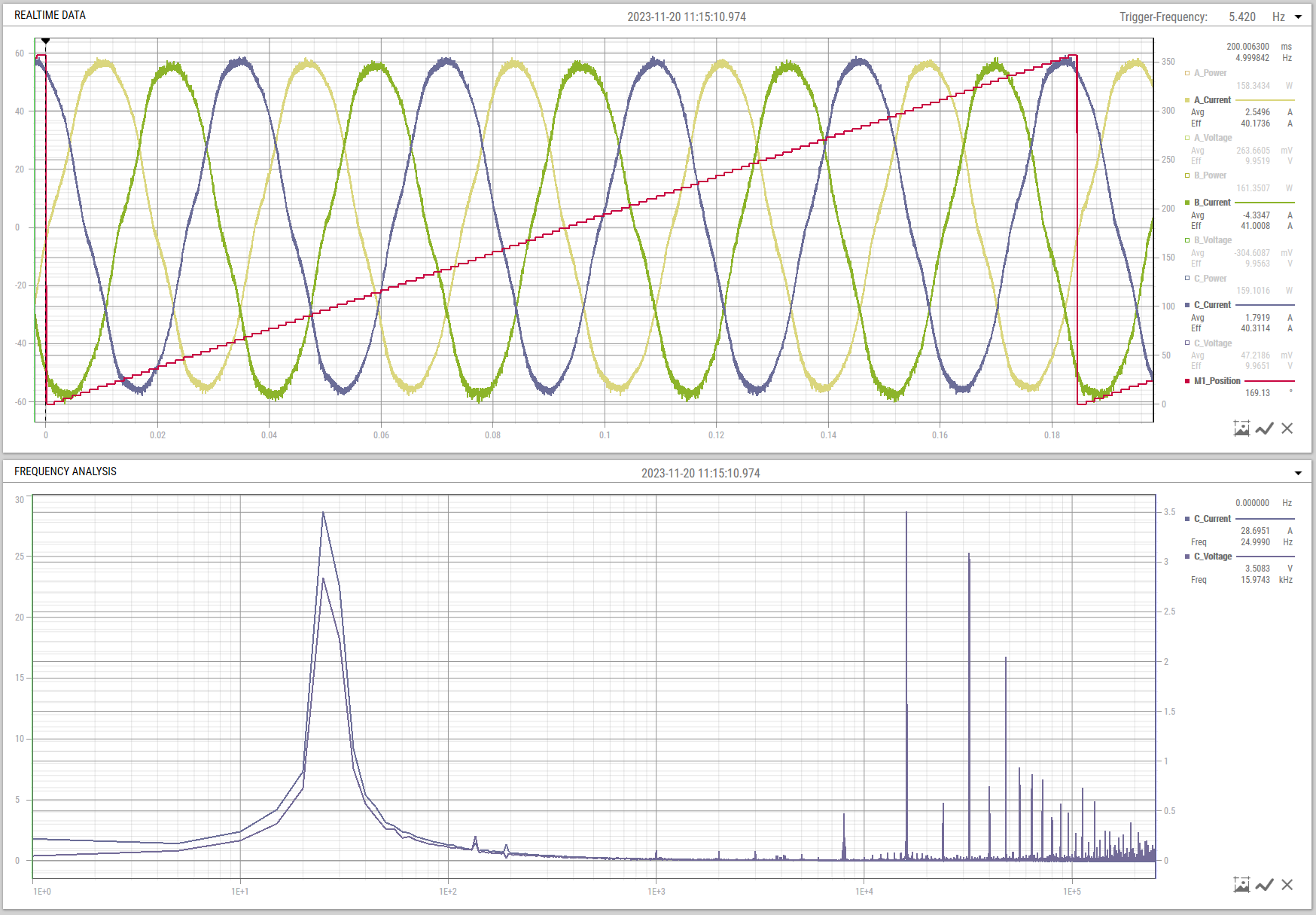

At the heart of the power analyzer is our intuitive data acquisition software, which allows extensive configuration and lets you start and monitor measurements. Intuitive visualization tools simplify analysis of acquired data. Saving settings and data is straightforward, enabling reliable reproduction of measurement routines.

The "parallel view" output of RAW data and calculated power analyzer data enables immediate identification of reasons for any deviations in the computed power metrics.

With highest accuracy, the analog and digital technology of the measurement cards captures current and voltage in real time. Maximum dynamics for high-frequency signal acquisition are ensured by the wide bandwidth and sampling resolution. Low signal latencies enable best-in-class synchronization. Even at high reactive power, the power analysis delivers precise results.

The consistently low measurement error of 0.05% of the respective power value ensures precise results, even with low range utilization. This guarantees utmost accuracy throughout the entire analysis.

The POWERAnalyzer LK601 provides outstanding dynamics across the entire measurement range thanks to sampling rates up to 10 MS/s, 16-bit A/D conversion, and optimal linearity in signal processing.

This ensures consistently precise results and high-accuracy data and power analysis up to full-scale utilization in ranges up to 1,000 V and 500 mA (external current sensor input).

Designed for modularity from the outset, the POWERAnalyzer LK601 is future-proof in terms of scalability and flexibility. Changing requirements can be addressed quickly and easily by adapting hardware and/or software — always staying up to date.

Benefit from continuous progress: Modern electric drives can comprise a variety of components to be tested — front and/or rear drive, in-wheel motors, inverters, gearboxes, cooling systems, battery modules, and more. The ability to expand and adapt the corresponding test system is therefore essential.

The power analyzer’s flexibly configurable base unit enables extensive expansion of your test setup. A range of options and an integrated CAN interface are available — whether for electrical, mechanical, thermal, or other measured variables. Power and efficiency: measure faster and easier with the POWERAnalyzer LK601.

With the POWERAnalyzer LK601 you can acquire up to six power channels simultaneously. This allows simultaneous power analysis of multiple polyphase motors with up to nine phases each.

In addition to high-precision measurement, accurate RAW data recording is a key capability of our POWERAnalyzer LK601.

The RAW data acquisition for analog and digital signals can record not only pure power values, but also 3‑channel RAW recordings of current and position.

The power analyzer also calculates power with sampling rates up to 10 MS/s, including active, apparent, and reactive power, as well as analysis of fundamentals and harmonic components.

Our power analyzer also functions as a mixed-signal recorder — all input signals can be captured with a single measurement system, whether DC, three-phase systems, or complete drivetrains including speed and torque signals.

With the POWERAnalyzer LK601, continuous power calculation in industrial environments is possible. In particular, data acquisition and analysis for determining the efficiency of electric motors and inverters of higher power classes is enabled by high sampling rates with consistently low measurement error.

With intelligent interfaces, the power analyzer integrates seamlessly into test bench and automation systems. Flexible adaptation to the desired test environment is possible at any time using the existing LabVIEW driver or via direct programming with SCPI or C#.

Power analyzers are high-precision measurement instruments used to test demanding electronic components. Given the accuracy requirements, careful calibration is essential. Our POWERAnalyzer LK601 can be set up by independent calibration laboratories in accordance with recognized standards.

In motor test benches and other drivetrain test setups, it is necessary to capture not only electrical variables but also mechanical signals of the motor such as speed, torque, and position. Only then can statements about the efficiency of electric machines be made. In addition to high accuracy, a major advantage of our dual motor card is the ability to directly connect a total of two motors. This allows both the DUT (device under test) and the load machine to be measured with a single device.

| Sampling rate | 200 kS/s | |

| Sampling resolution | 16 bit | |

| Signals | Position (angle), speed | |

| Power supply | 5 V / 400 mA | short-circuit-proof |

| Encoder connector | D‑SUB15 | female |

| Torque connector | D‑SUB9 | male |

| Differential | TTL 5 V (RS422) | A/AN, B/BN, Z/ZN | 10 MHz max. |

| HTL 30 V (max) | A/AN, B/BN, Z/ZN | 400 kHz max. | |

| Single‑ended | TTL 5 V (RS422) | A, B, Z | 1 MHz max. |

| HTL 30 V (max) | A, B, Z | 200 kHz max. |

| Analog (unipolar) | 0–5 V / 0–10 V | 15 kHz @ −3 dB |

| Analog (bipolar) | ±2.5 V / ±5 V / ±10 V | 15 kHz @ −3 dB |

| Digital | TTL 5 V (RS422), A/AN | 1 MHz max. |

If you have questions or need more information, feel free to reach out during our business hours via the contact form or by phone. We look forward to your inquiry!

Below you will find additional fundamentals related to our power analyzer.

A power analyzer is a high-precision electrical measurement instrument used to capture, measure, and analyze various electrical parameters. Also known as a power analysis instrument, a power analyzer measures a variety of values within electrical circuits, including current, voltage, and frequency, as well as power factor, apparent power, active power, and reactive power. After acquisition, these parameters are evaluated with software to yield insights into the performance of electronic systems.

Such systems are used not only to optimize efficiency and identify faults in electrical circuits, but also to help verify and improve the safety and quality of electrical installations. For this reason, power analyzers have seen increased adoption in recent years, particularly in the context of sustainability.

The operating principle of a power analyzer is based on measuring energy flow in AC and DC circuits. Specifically, the effective value (RMS) of the electrical signal is measured to determine circuit power, with the average value taken over the full frequency cycle of the alternating current.

Modern power analyzers can digitally identify frequency cycles, enabling precise data on the effective RMS period during power conversion in addition to voltage and current.

After capturing the relevant values, the power analyzer computes the corresponding power with very high accuracy using mathematical calculations.