Compared to conventional CCC welding control (Constant Current Control), adaptive weld control offers significant advantages. Above all, this includes the property of regulating disturbance variables / influences such as shunts or sheet thickness changes (due to manufacturing tolerances). As a result, this process control deliver a reliably high weld quality, especially in manufacturing industry. The algorithms developed and used by MATUSCHEK (first time in the 1990s) have been continuously developed and are still the state-of-the-art technology worldwide.

MASTER is a control method developed for steel welding and based on the principle of reference welding process. During reference welding, the current is constantly controlled to the set CCC value. A good joint is achieved without disturbing influences with the optimum selection of welding time, current and electrode force. The data of current and electrode voltage measured during this weld are stored. After switching to the control mode, all subsequent welds are controlled according to the stored MASTER reference data of the good weld.

These resistance welding control processes necessarily require fast power sources. Medium frequency inverters with a reaction time of 1 millisecond - at 1 000 Hz inverter frequency - fulfil this requirement. Thyristor controllers with a reaction time of 10 or 20 milliseconds are too slow for adaptive MASTER control.

The adaptive MASTER control compensates for:

The MASTER control method compensates for the various influences by increasing (or decreasing) the current intensity and extending (or shorten) the welding time. The time extension can be limited. The monitoring of weld spatter is carried out by issuing a corresponding status message.

Due to the optimal adaptation to each individual spot, the required strength of the welded joint is guaranteed in wide areas.

AluMASTER is an adaptive control method for aluminium welding that compensates for the following process disturbances and variations:

The AutonomousMASTER represents a new dimension as an adaptive control method for steel welding applications. With this method, no parameterization or presettings for the spot are necessary. That means:

The MicroMASTER is an adaptive control method for small part joining.

The following problem is known in many small part applications:

The components to be welded, often only millimeters thick, may only sink into a very narrow

tolerance band during fusion, otherwise they will not hold, because they have not been

sufficiently or too strongly welded (through-welded). Once parameters for an optimal curve have

been found, they are often only valid for the following welds for a short time due to various

influences such as component tolerances, electrode cooling temperature variations, positioning

inaccuracies or dirty electrodes. Quality problems and their costly consequences are the

result.

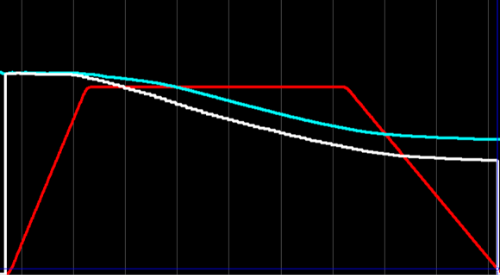

The MicroMASTER solves this problem by welding to the target position with micrometer accuracy using a trajectory. The principle is easy to operate and works as follows:

Predestined for this control process are the linear precision weld heads of the LSK series with their integrated high-resolution position measuring system.

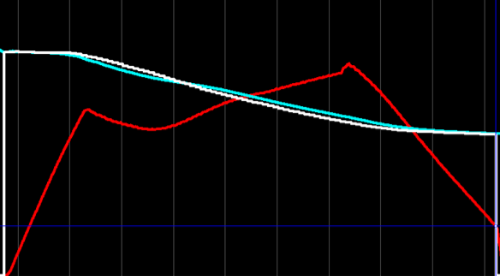

Example:

| Red: | current |

| Blue: | actual penetration |

| White: | reference penetration |

| Difference: | 112 µm |

| Red: | current |

| Blue: | actual penetration |

| White: | reference penetration |

| Difference: | 3 µm |

For each weld, the SPATZ+ weld timer records the curves for all electrical and mechanical signals. This data is analysed and summarised to one single value, the NUGGETIndex. This quality parameter provides the correlation to the spot diameter of each weld spot, which directly correlates with the resulting weld nugget.

During MASTER setups, the NUGGETIndex limits are automatically calculated. The NUGGETIndex, as a 100 % inline NDT system in production, therefore does not require any statistical data. This helps to drastically reduce cost-intensive destructive testing.

|

SUPPORT, SALES AND TRAINING We would be happy to advise you on the selection of suitable solutions for your individual welding tasks and inform you about our training portfolio. |