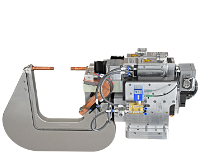

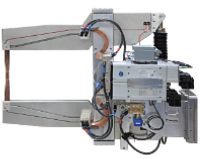

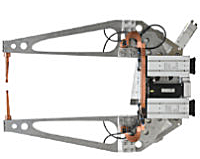

An essential requirement for a good aluminium or steel weld spot is the reproducibility of the electrode force. In all gun positions this always must be guaranteed, even at interferences. Matuschek servo weld guns are equipped with a servo-electric actuator for building up the force (with integrated encoder and force sensor) and a likewise servo-electric actuator for optimal compensation of the gun weight in electrode direction (compensation). In combination with our spot welders we provide high quality systems for automotive and manual applications.

The SPATZ+ technology control system evaluates motor current, encoder and force signals from the gun in real time and reliably compensates for disturbances through fast evaluation and feedback to the main motor within a few milliseconds.

An asymmetrical distribution of the welding force of the electrodes to the component caused by

is compensated down to a few Newton by the low-friction servo-electric motor compensation (servo balancing) in combination with adaptive control. Welding guns equipped with these technologies enable reproducible and reliable spot welding of even the most demanding aluminium and steel sheet combinations. It increases the level of quality significantly.

Matuschek weld guns are available in C, X and K design in scalable sizes.

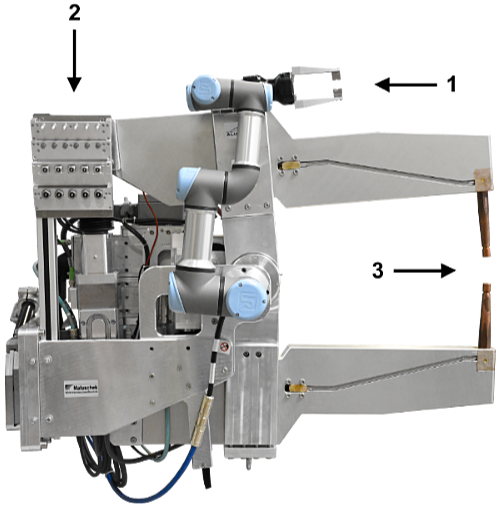

The addition of the patented SPATZ+ CoboFeed to Matuschek's ServoSPATZ+ welding systems opens up completely new possibilities in line architecture. In automated series production, the SPATZ+ CoboFeed is used to feed e.g.

to weld them directly in the body or in the component. This allows production lines with great savings potential to be realized.

The SPATZ+ CoboFeed consists of:

To weld nuts or bolts in the body, the corresponding components previously had to be fed to a stationary projection welding system in a separate process step. With the CoboFeed, this can be done directly in the car body in parallel with other process steps, such as spot welding!

One challenge in automotive joining technology is the joining of different materials, especially aluminum with steel.

With the SPATZ+ aluminum complete system, consisting of control, CapClean, as well as servo gun and CoboFeed, all joining variants, Al-Al, steel-steel with spot welding, as well as Al-steel with rivet welding, can be carried out in one process sequence!

In addition to the classic spot welded joints, aluminum is also joined to steel in a process-safe manner with the aid of weld rivets fed by CoboFeed.

For this purpose, during the approach of the tongs, the gripper of the CoboFeed(1) removes the rivets from the magazine(2) and positions them on the component between the electrodes(3) for welding.

This can be done in any position in the room. After the welding processes in the component, the CoboFeed automatically refills its magazine from a filling station.

Due to its simple concept, the SPATZ+ CoboFeed is very robust, does not require compressed air, unlike most feed units, and thus optimally complements the compressed air-free ServoSPATZ+ overall concept.

The SPATZ+ CoboFeed can be used as an "add-on" on both steel and aluminum welding guns, depending on the application, and uses all the welding process advantages of the adaptive MASTER controls!

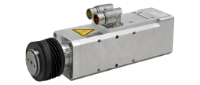

For all SPATZ+ servo applications (manual or robotic welding), whether in automotive industry, in special applications such as projection machines or as a welding head, e.g. for hard metal welding, we manufacture the appropriate high-precision, low-friction actuators.

With maximum forces in the range of 3 kN - 20 kN, absolute value encoder and partially integrated force sensor, they bring the force to the welding point in a reproducible and precise manner. They can be used in heavy duty applications such as automotive industry.

Examples actuators:

| Lift: | 110 mm (4.33") |

| Spindle pitch: | 10 mm (0.39") |

| Fmax: | 5 000 N |

| Traversing speed vmax: | 333 mm/s (13.11"/s) |

| Weight: | 5.6 kg (12.35 lbs) |

| Anti-twist security: | No |

| Position measuring unit: | Encoder |

| Internal force measurement: | No |

| Lift: | 180 mm (7.09") |

| Spindle pitch: | 10 mm (0.39") |

| Fmax: | 10 000 N |

| Traversing speed vmax: | 500 mm/s (19.69"/s) |

| Weight: | 15.7 kg (34.61 lbs) |

| Anti-twist security: | Yes |

| Position measuring unit: | Encoder |

| Internal force measurement: | Yes |

WELD TIMER The SPATZ+ servo guns and actuators are combined with SPATZ+ weld timers. |

|

|

SOFTWARE The entire setting, parameterization and visualization of the welding parameters is carried out by the SPATZ software family. |

|

|

SUPPORT, SALES AND TRAINING We would be happy to advise you on the selection of suitable solutions for your individual welding tasks and inform you about our training portfolio. |