Sheets made of aluminum can also be joined to one another using resistance spot welding. Challenging is the higher electrical conductivity. The thermal conductivity also differs from steel. This requires a fundamental increase in the electrical current. When spot welding aluminum, deviating conditions, such as shunt effects or varying surfaces, can lead to irregular results. Also the aluminum oxide will have an impact on the resulting weld outcome. Due to the material properties of aluminium, we can summarize the following challenges:

| Challenge: | Solution: |

|---|---|

| - Low electrical resistance | High currents |

| - High thermal conductivity | Short process times |

| - Oxidizing surfaces | Variable start conditions |

| - Mandatory clean electrodes | Regular electrode cap cleaning |

- Low electrical resistance:

High currents

- High thermal conductivity:

Short process times

- Oxidizing surfaces:

Variable start conditions

- Mandatory clean electrodes:

Regular electrode cap cleaning

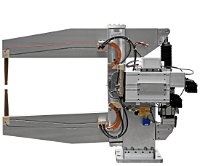

With the AluSPATZ+ complete system, MATUSCHEK offers a future-proof customer-specific complete solution. This means that the reliable resistance welding process of aluminium will no longer be a problem in the future when implementing your projects. Constant reproducible results can be achieved with the AluSPATZ+ complete system , both for joining of structural components, extruded profiles and 3-sheet connections, and for series production. Even different aluminum alloys can be handled applying our control technique

It consists of the following components:

2- and 3-sheet combinations of e.g. material classes AA 5xxx and AA 6xxx with single sheet thicknesses from 0.8 mm to 3.0 mm can be reliably spot welded in automated serial production with one weld gun equipped with one electrode cap geometry only, independent from

This flexibility results in a significant reduction of needed equipment for the joining process and floor space in comparison to the application of mechanical joining methods. Thus, for the same output less equipment and floor space is needed.

Due to the fact that the AluSPATZ+ equipment is just a "simple" spot welding system as known from steel applications it is principally characterized by a higher grade of availability compared to mechanical joining methods or spot welding controllers using additional base material and hardware. E.g. for prevention of direct contact between copper electrodes and aluminium sheets. The availability of AluSPATZ+ when spot welding aluminium is the same as for spot welding application of steel, just providing higher electrode life times. No additional feeding or other guiding equipment is needed on the weld gun. For the same output less equipment and floor space is needed!

The costs for a welded joint connection of aluminium sheets are basically the costs for the weld energy! The energy needed for joining e.g. the 2-sheet combination of 3.0 mm AA 5754 + 2.5 mm AA 6082 is about 30 KWs per weld joint. Provided a rate of 0.08 € per KWh this corresponds to a cost of 0.0008 € per weld spot. Secondary costs are the costs for the consumables only, which are the electrodes and the cleaning wheels. The life time of a pair of electrodes when applying AluSPATZ+ equipment is about 10,000 weld spots. Life time of a cleaning wheel is > 250,000 weld spots.

Example: The energy costs for the spot welded joints in an aluminium body of a car model with a production volume of 200,000 cars per year and 4,000 spot welded joints per car are 640,000 € per year. Whereas in case riveting would be selected as joining method instead of spot welding the costs for the rivets only for the same car model would be 20,000,000 € per year, based on a price of 0.025 € per rivet. That is about 30 times higher costs compared to RSW.

|

WELD TIMER Here you will find further product solutions of the AluSPATZ+ series. |

|

|

SUPPORT, SALES AND TRAINING We would be happy to advise you on the selection of suitable solutions for your individual welding tasks and inform you about our training portfolio. |