There are different types of welding methods for joining sheet metal made of steel. MIG, TIG or resistance spot welding (RSW) can here be named in the first place. Shielding gas is needed for TIG applications, which increases the efforts for an automated process. Therefore RSW is used to a great extent, especially in the automotive industry for joining sheet metals. The heat input is generated by injection of a current. In conjunction with the specific resistance this current results in melting the metal. We offer highly professional spot welding equipment for this purpose, which ensures the best possible result in series production. Our products are characterized by the following properties:

With the combination of

Matuschek offers a complete package for industrial applications, which not only promises the implementation of all these requirements, but also implements them safely! Furthermore the weld times can be reduced and therefore speed up the production process chains. Increasing weld quality also means reducing cost for destructive quality enforcement tests.

Because only if these requirements can be reliably implemented, savings over the production cycle can be achieved which exceed the additional investment at the beginning many times over. Do the math yourself. We look forward to helping you save money with our spot welder.

The increased application of high-strength steels in the car industry causes a big problem in welding of sheet metals. Differences in the steel elasticity and the hardening of the sheets which has been caused by cold forming, result in poor fit-up and thus in increased sheet bulging which differ from part to part and occur even inside the parts; a determination before welding is not possible. Since, in most cases, sheet bulging is not compensated by fixing with clamps and pressure pads or similar tools, the welding gun is to provide the necessary force.

Without adaptive welding current control, the compensation of the disturbance "sheet bulging" is, for all welding spots, managed through an extraordinary increase of the gun force only. However, the diameters of the welding spots which are located in the areas without sheet bulging are too small because the electrode force has been set too high. Instead of the electrode force increase, therefore, the application of an adaptive current control (adaptation of welding current and welding time) is the better solution of this problem.

The subject of liquid metal embrittlement is currently once again a highly topical issue in engineering circles. After the reduced use of TRIP steels from car body construction, which were characterized by strong variations in rebound behavior after forming and therefore tended to have poor fits, and were therefore strongly affected by liquid metal embrittlement, for some time now it has been high-alloy and ultra-high-strength galvanized steel grades with yield strengths > 1 000 N/mm² that have brought the subject of liquid metal embrittlement back into the limelight.

Due to the high strengths, the usual disturbance variables known in series production, such as sheet bounce due to poor fits and misalignment of the electrodes to the sheet, lead to increased stress on the sheet surfaces with simultaneous thermal stress.

Meticulous care in forming, plant design and fixture and clamping technology are the so far known ways to reduce cracking due to liquid metal embrittlement of the steel.

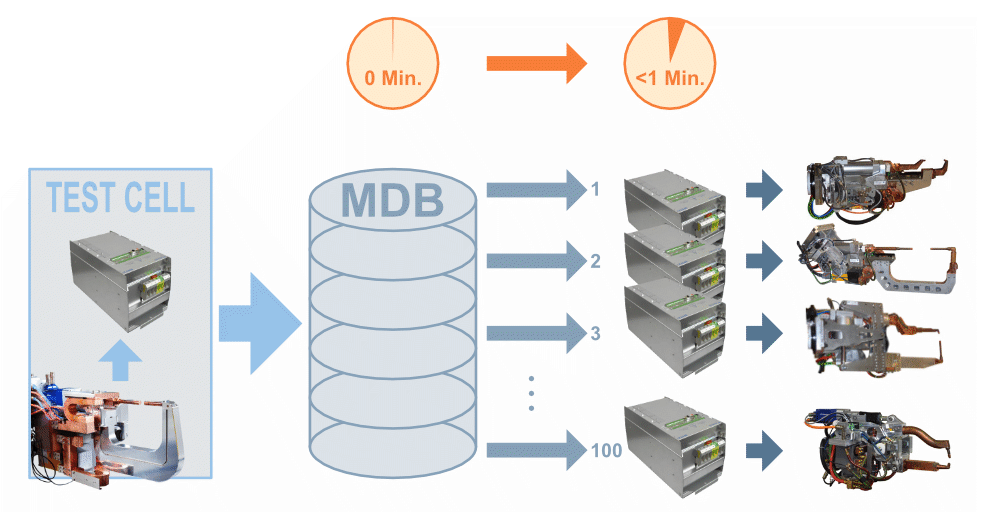

The ServoSPATZ technology (combined control of the welding current and control of the electrode axes in one device (combined control)), which has been proven for more than 10 years, could be extended by the NC technology, the adaptive control method ServoMASTER and NUGGETIndex NC®. This significantly reduces or completely avoids the formation of cracks.

|

WELD TIMER Here you will find the product solutions in the steel welding section of the SPATZ+ series. |

|

|

SUPPORT, SALES AND TRAINING We would be happy to advise you on the selection of suitable solutions for your individual welding tasks and inform you about our training portfolio. |