Our 1 000 Hz MF inverters have been specially developed for use in the automotive industry and are available as 400, 600 and 900 amp versions. The inverter in combination with our weld timer is the heart of every MATUSCHEK medium frequency welding system. In a master-slave configuration, which requires two SPATZ+ inverter, higher output currents are also possible. For example, for use in aluminium welding.

The following additional features distinguish our SPATZ+ weld timer:

| Weld spot selection: | 32 Bit |

| Programs: | 1 024 |

| Welding impulses per program: | 16 |

| Control types: | MASTER, CCC, CPC, CVC |

| Welding parameter monitoring: | yes |

| Stepper function: | at CCC, CPC and CVC |

| Power program: | yes |

| Current rise / current fall: | yes |

| Measuring signal inputs: | Current, voltage, force, displacement |

| 1 x Proportional valve output: | 0 - 10 V DC or 4 - 20 mA |

| Interfaces: | USB, Ethernet |

| Fieldbus cards: | PROFIBUS-DP, DeviceNet, PROFINET, EtherCAT, EtherNet/IP |

| Digital I/O: | 16 / 11 |

| Cooling: | Air-cooling (ambient air temperature max. 45 °C / 113 °F) or water-cooling |

| Protection type: | IP20 |

| Dimensions (H x W x D): | 425 x 200 x 320 mm (air-cooled), 16.7 x 7.87 x 12.6 in 425 x 200 x 260 mm (water-cooled), 16.7 x 7.87 x 10.2 in |

Weld spot selection:

32 Bit

Programs:

1 024

Welding impulses per program:

16

Control types:

MASTER, CCC, CPC, CVC

Welding parameter monitoring:

yes

Stepper function:

at CCC, CPC and CVC

Power program:

yes

Current rise / current fall:

yes

Measuring signal inputs:

Current, voltage, force, displacement

1 x Proportional valve output:

0 - 10 V DC or 4 - 20 mA

Interfaces:

USB, Ethernet

Fieldbus cards:

PROFIBUS-DP, DeviceNet, PROFINET, EtherCAT, EtherNet/IP

Digital I/O:

16 / 11

Cooling:

Air-cooler (ambient air temperature max. 45 °C / 113 °F)

or water-cooler

Protection type:

IP20

Dimensions (H x W x D):

425 x 200 x 320 mm (air-cooled), 16.7 x 7.87 x 12.6 in

425 x 200 x 260 mm (water-cooled), 16.7 x 7.87 x 10.2 in

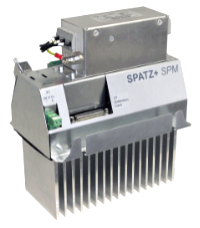

In order to upgrade the SPATZ+ weld timer to the ServoSPATZ+ technology controller, only one (or two) SEC extension cards and one (or two) SPM power modules are required which are mounted in the switch cabinet next to the controller. With this upgrade it is possible to control up to two servo actuators.

| U2N: | 560 V |

| I2N: | 10 A |

| I2max: | 32 A |

TRANSFORMERS The SPATZ+ weld timers are combined with SPATZ+ transformers. |

|

SERVO WELDING GUNS The SPATZ+ weld timers are combined with SPATZ+ servo welding guns. |

|

FIELDBUS- & EXTENSION CARDS To extend connectivity and variable system integration, the SPATZ+ weld timers are upgraded with SPATZ+ fieldbus cards and SPATZ+ extension cards. |

|

|

SOFTWARE The entire setting, parameterization and visualization of the welding parameters is carried out by the SPATZ software family. |

|

|

SUPPORT, SALES AND TRAINING We would be happy to advise you on the selection of suitable solutions for your individual welding tasks and inform you about our training portfolio. |